You sit on it, sleep on it, and probably open packages filled with it, but have you ever stopped to ask, What is foam made of? I’ve wondered the same thing. It’s more than just a soft, squishy material.

If you’re picking out a new mattress, diving into a DIY project, or just curious, knowing a bit more about foam can really help you make smarter choices.

In this guide, I’ll walk you through what foam is made of, how it’s created, and the types you’re most likely to run into. You’ll also learn where foam shows up in everyday life, how it affects the environment, and how to choose the right kind for your needs.

Curious what gives foam its shape, feel, and function? Let’s take a closer look

What is Foam Made Of? Understanding Its Composition

Foam forms when gas bubbles are trapped in a liquid or solid, creating a light, airy structure. If you’re asking what foam is made out of, it typically includes polyols and isocyanates, which react to form polyurethane.

Blowing agents create bubbles, catalysts speed up the reaction, and surfactants control bubble size and spread. Together, these materials shape foam’s texture and performance.

By adjusting the ingredients, manufacturers produce foam that’s flexible or rigid. This makes it useful in everything from cushions and mattresses to packaging and insulation.

The final result depends entirely on its chemical composition and production method.

Different Foam Types and Their Properties

Foam comes in many forms, each with its own feel, function, and use. Here’s a breakdown of the most common types and what makes them stand out:

1. Polyurethane Foam

Polyurethane foam is produced by reacting polyols with isocyanates, resulting in a versatile material used in mattresses, cushions, and insulation.

Variations like high-density and low-density polyurethane foam are designed for specific uses, with high-density foam offering more durability and firmness, while low-density foam is softer and more flexible, making it ideal for comfort applications.

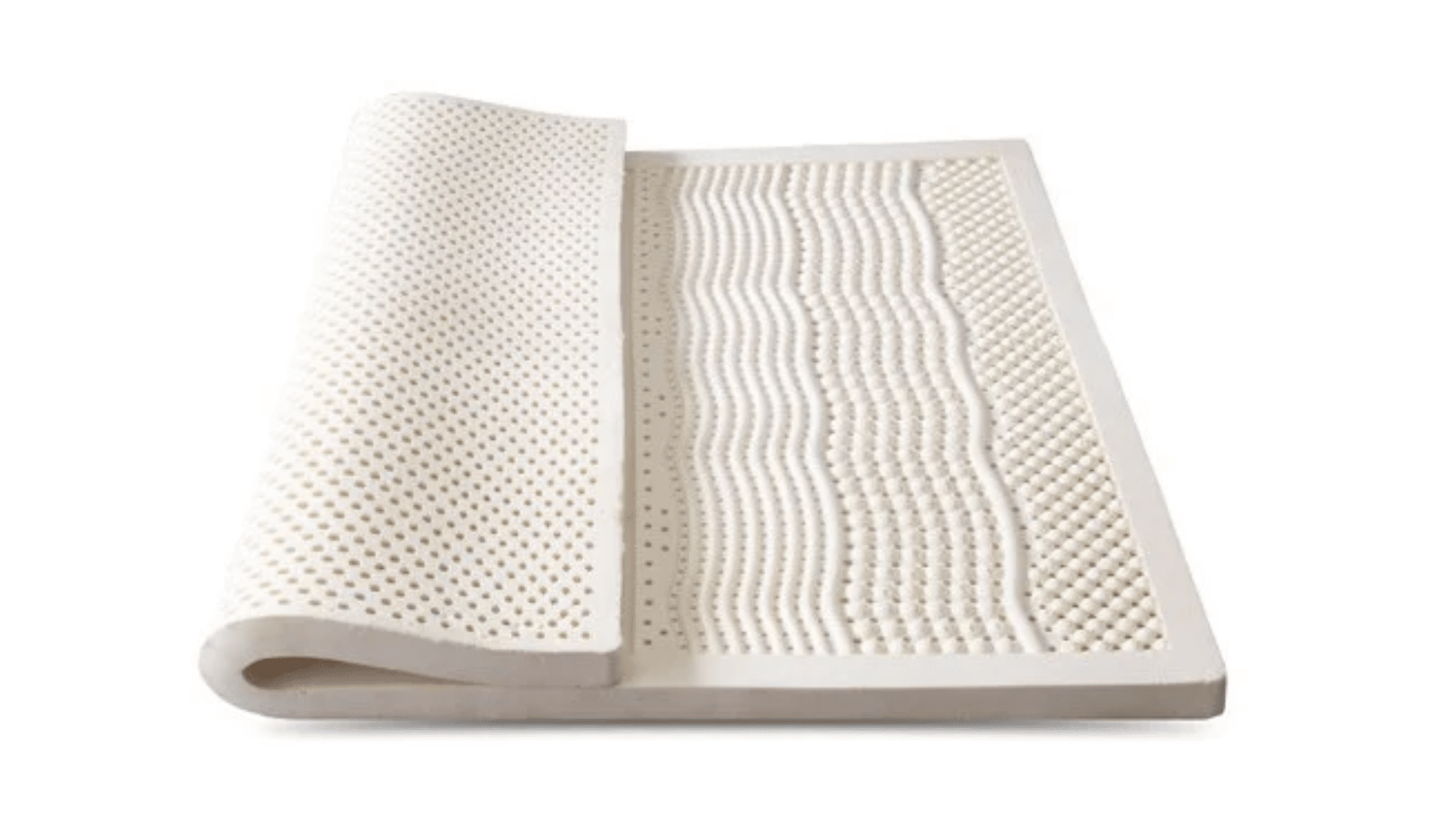

2. Latex Foam

Latex foam can be natural, derived from rubber trees, or synthetic, made from petrochemicals.

Natural latex offers superior elasticity, comfort, and breathability, while synthetic latex is more cost-effective but may lack some of the benefits of the natural material.

Both types are popular in mattresses and cushions due to their supportive and breathable properties.

3. Polystyrene Foam (Styrofoam)

Polystyrene foam, commonly known as Styrofoam, is created by expanding polystyrene beads using steam or chemical blowing agents.

It is lightweight, insulating, and used primarily in packaging, insulation, and disposable products like cups and plates. Its closed-cell structure makes it a great insulator, though it’s not biodegradable, raising environmental concerns.

4. Memory Foam

Memory foam is a viscoelastic material that responds to heat and pressure, molding to the shape of the body.

Commonly used in mattresses and cushions, it provides personalized support, helping relieve pressure points and improve comfort.

This foam returns to its original shape once the pressure is removed, offering excellent durability and comfort.

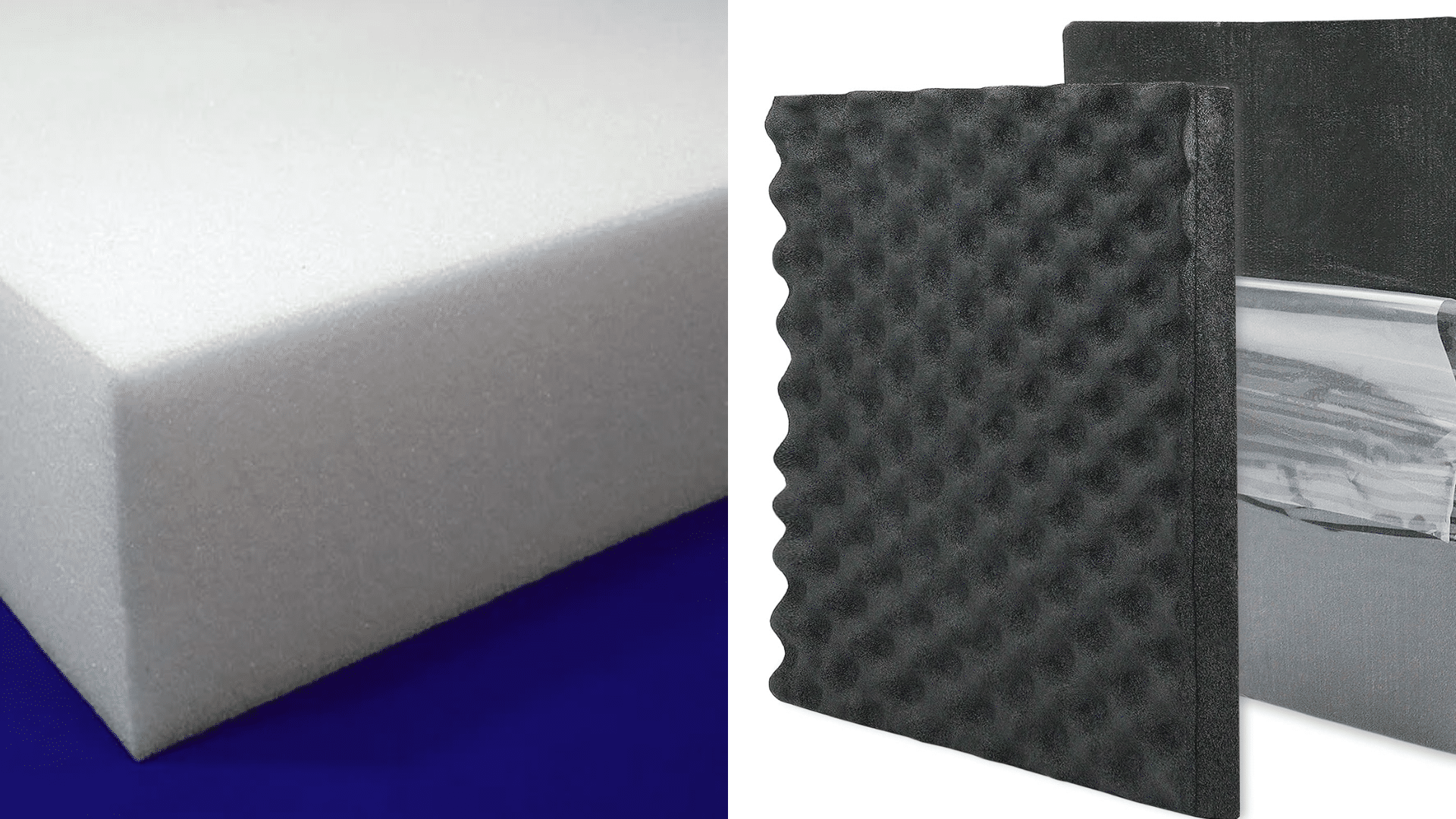

5. Closed-Cell vs. Open-Cell Foam

Closed-cell foam has sealed cells that make it more rigid and impermeable to air and water, often used in insulation and flotation devices.

Open-cell foam, on the other hand, has interconnected cells, making it more flexible and breathable, ideal for applications like cushioning, soundproofing, and filtration. Both types offer unique benefits based on their structure.

Foam in Everyday Applications

Foam is all around us, playing a big role in daily life. Let’s look at how it’s used across different industries for comfort, protection, and support.

Foam in Furniture (Mattresses, Cushions)

Foam in furniture, such as mattresses and cushions, is chosen for its comfort and support.

Memory foam, latex foam, and polyurethane foam are commonly used for their ability to contour to the body and provide pressure relief.

High-density foams offer firm support, while low-density foams provide softness and cushioning, making them ideal for both comfort and durability in furniture.

Foam in Packaging

Foam is essential in packaging, offering protection to fragile items during shipping. Types of foam, like polystyrene and polyurethane, are commonly used for their shock-absorbing properties.

These foams ensure items stay intact by cushioning them from impact and vibration. Custom foam inserts are often used to fit products, preventing movement within packaging during transit, securely.

Foam in Construction

Foam is widely used in construction for insulation, soundproofing, and waterproofing. Closed-cell foam offers excellent thermal insulation, helping to maintain energy efficiency in buildings.

Open-cell foam is often used for soundproofing, reducing noise transmission between rooms. Foam can also be used as a waterproofing barrier, protecting buildings from moisture damage and enhancing overall structural integrity.

Foam in Automotive and Aerospace

Foam plays a crucial role in automotive and aerospace applications. In cars, foam is used in seats, dashboards, and door panels for comfort, sound insulation, and impact protection.

In aerospace, foam is used for insulation in aircraft, helping to regulate temperature and provide soundproofing. Its lightweight properties are also valuable in reducing the overall weight of vehicles and aircraft.

DIY Foam Creation at Home

Learn how to create foam at home for various projects, including crafting and practical applications like insulation and packaging.

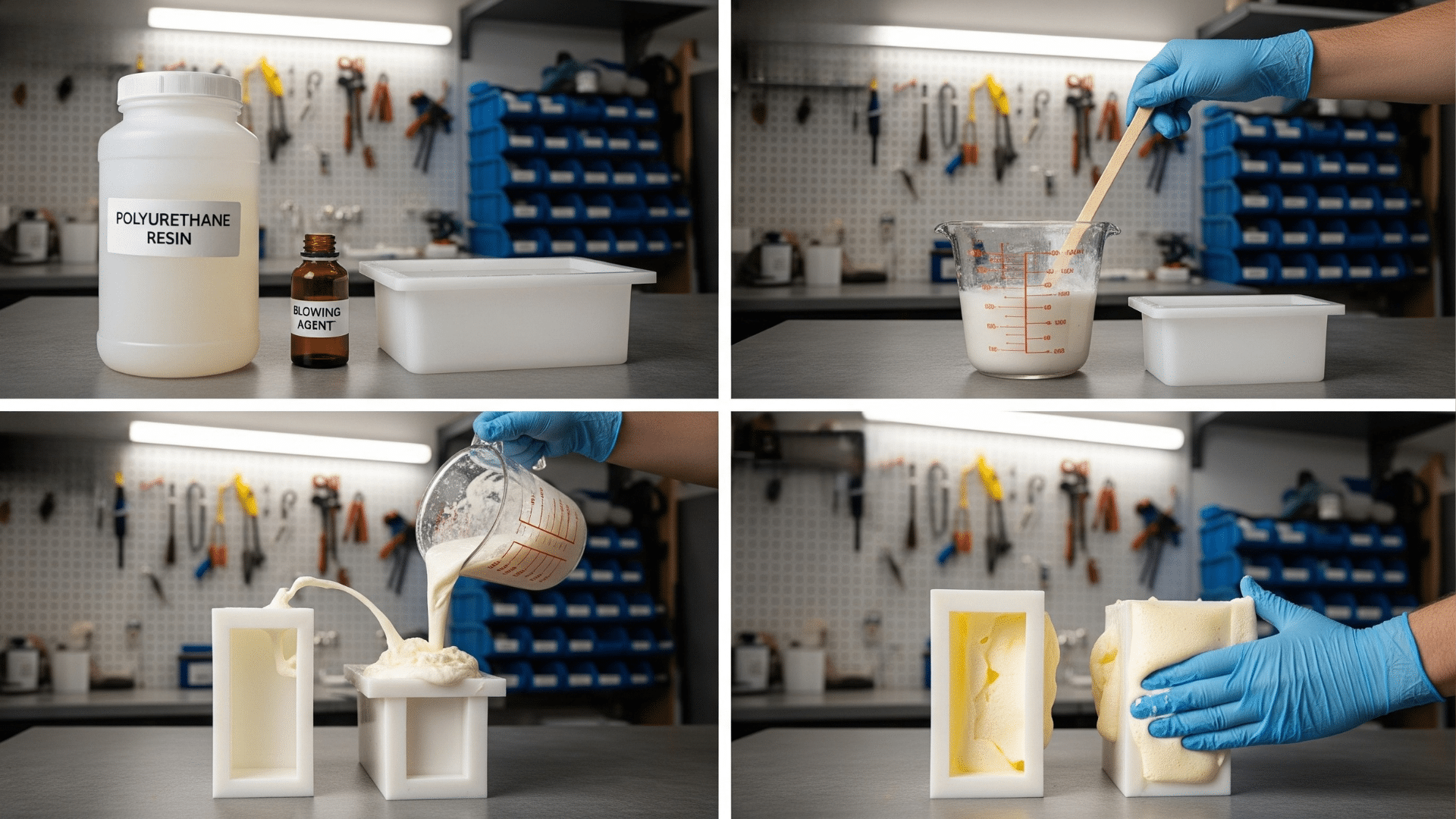

DIY Foam for Insulation or Packaging

Creating your own foam for insulation or packaging is simple and cost-effective. It’s perfect for DIY projects and can be customized to fit your specific needs.

Step 1: For insulation foam, gather polyurethane resin, a blowing agent, and a mold to pour into.

Step 2: Combine the polyurethane resin with a blowing agent in a mixing container. Stir to activate the foam-making process.

Step 3: Carefully pour the foam mixture into a mold and allow it to expand and set. This will become your insulation foam.

Step 4: Let the foam cure completely before using it for insulation. Check its hardness and flexibility before application.

Simple Foam Recipes for Crafts

Creating foam for crafts is a simple and enjoyable DIY project. It’s perfect for making decorative items or crafting custom cushions for home projects.

Step 1: Gather materials such as white glue, borax solution, and a mixing container. These ingredients will help form the foam base.

Step 2: In the container, combine 1 part borax solution with 2 parts white glue. Stir thoroughly until foam begins to form.

Step 3: Keep stirring until the mixture thickens and forms foam. This foam will be perfect for cushioning or craft projects.

Step 4: Once the foam has formed, mold and shape it into the desired craft project or cushion. Allow it to cure before use.

Environmental Considerations in Foam Production

Examine the environmental impact of foam production, including resource use, carbon emissions, and potential waste management solutions.

Foam’s Environmental Impact

Foam production contributes to environmental concerns due to its carbon footprint, waste generation, and non-biodegradability.

The chemicals involved in production, such as hydrofluorocarbons (HFCs) and other petroleum-based products, emit greenhouse gases that contribute to global warming.

Additionally, foam waste can accumulate in landfills and pollute ecosystems, harming wildlife. Sustainable solutions are essential to mitigate these impacts.

Sustainable Foam Alternatives

Eco-friendly foam alternatives offer promising solutions to reduce environmental harm.

Biodegradable foams, made from natural materials like starch, or plant-based foams, made from renewable resources such as soy or hemp, are gaining popularity.

These alternatives break down more easily in the environment, reducing waste. Additionally, innovations like mushroom-based foams and recycled materials are helping to minimize the ecological impact of foam production.

Foam Recycling

Recycling foam products presents significant challenges due to the material’s lightweight, non-biodegradable nature.

While some foam types can be recycled into new products, the process is not widely available and requires specialized equipment.

Opportunities exist to improve foam recycling programs by developing better collection systems, technology for reprocessing foam, and creating markets for recycled foam products, thus reducing landfill waste.

Choosing the Right Foam for Your Needs

Selecting the right foam depends on your specific project, whether it’s for comfort, insulation, or protection. Here are the key points to consider:

- Consider the foam type

- Evaluate density and firmness

- Match the foam to the intended use

- Think about durability and lifespan

- Factor in comfort and support

Understanding the right foam type will ensure you get the most out of your material, either for a DIY project or product purchase.

Conclusion

Now that you’ve got a clear understanding of what foam is made of, you can make smarter choices for your next project, whether it’s for comfort, insulation, or something crafty.

I’ve found that knowing how foam is made and what types are out there really helps when deciding what works best for your needs.

Think about things like density, firmness, and where you’ll be using it. If you’re aiming to cut down on waste, you might want to explore some eco-friendly options too.

Foam isn’t just soft padding; it’s a super versatile material you probably use more often than you realize.

Want to keep learning? Check out my other blogs for easy DIY tips, material guides, and home improvement ideas you can actually use.